Collaborative Product Development: How Customized Brake Solutions Give OEMs an Edge

Share this

Here’s a team-up that seems out of left field: John Deere and … NASA?

It’s true: John Deere collaborated with NASA’s Jet Propulsion Laboratory to create a GPS system that makes self-driving tractors more accurate with reliable, real-time satellite data. It’s a move that could advance agriculture vehicles into a new autonomous age.

Success can result when companies work together toward a common goal. Engineering heavy-duty equipment, in particular, demands that everyone brings their best. Sometimes, such projects require looking outside your walls.

When available off-the-shelf brakes aren’t cutting it for your vehicle design, it’s time to turn to a partner and work together to find customizations that deliver a tailored solution and provide a competitive advantage.

Collaboration Offers Valuable New Perspectives

If you’re challenged by a product design issue involving the braking system, it makes sense to work with a brake specialist that may see things you don’t. The years of real-world experience behind these unique perspectives could open up avenues you — and your competitors — might have missed.

Innovation Demands Collaboration

If you want to be innovative, you have to be collaborative.

While many advancements likely began as a spark in one person’s mind, they were brought to life by the combined efforts of innovators who wanted to make a real (and better) difference.

Effective collaboration brings together complementary skills and cross-functional teams to achieve breakthroughs that wouldn’t have been reached had each individual or organization been limited to what they already had available. Sharing these resources keeps innovation flowing, and being a part of that flow is crucial to staying ahead.

Advancements in off-road vehicle brake systems continue in a similar way.

Take riding lawn mowers, for example. Every landscape is different, and many — especially on private residences — are complex and require tight turns and precise maneuverability. Riding mowers have evolved to tackle not just the open fields, but smaller spaces, too. The need for high levels of precision in control will be a constant.

More advances will happen, and if you don’t want to be left behind, you need to lean on a partner who helps you rise above.

Learn More: 7 Reasons for Brake Failure in Heavy Equipment and How to Avoid Them

Stages of Collaborative Development

There’s no one right way to collaborate, but we’ve found an approach we think is effective because it yields positive results. Here’s a hypothetical scenario where you’ve sent a message to Hayes online.

First Contact

One of our sales representatives or business development managers receives your message. We reply quickly to discuss what you have in mind for your vehicle. If it’s in our wheelhouse, we’re eager to take it on.

Engineers Join the Conversation

Our engineers want to get as many specifications from you as possible early in the design process, such as dimensions and weight limits. They’ll ask questions about what kind of performance you need from the braking systems and what requirements (or regulations) apply to the vehicle … how much brake torque the vehicle needs, what grade of hill it will need to park on, etc. The team even accepts drawings and creates a 3D model for a clearer picture as the project takes shape.… what size master cylinders, what clamp force the vehicle needs, which calipers will work best, etc.

Once the engineers join, they remain involved throughout the project.

A Small, Dedicated Team

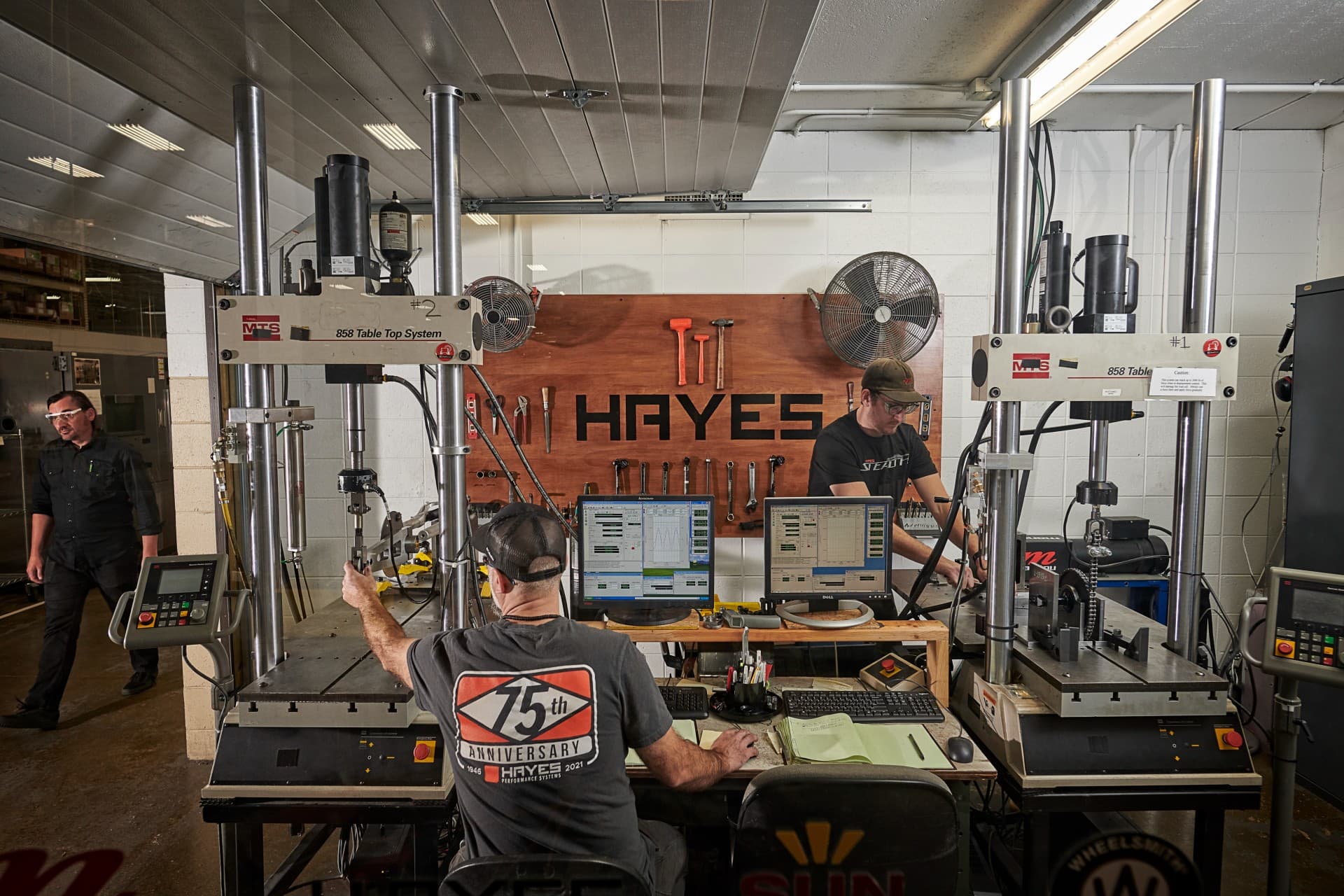

Hayes will dedicate 2-4 people to your project, but you have access to all of our resources. It’s not unheard of for someone outside the project (or from a different department) to offer assistance. Everyone here wants you to succeed.

You won’t get passed around or have to talk to someone new every time you’re in touch. We want to earn your trust, and a tight focus on this collaborative relationship is important to us.

How You Ultimately Benefit

Your biggest benefits from collaboration with Hayes: assurance and reduced risk. If an existing product doesn’t fit your specifications, you don’t need to search anywhere else for the solution. Instead, keep in contact with the team you know and discuss where we can go with customizations.

What’s more, the risks and expenses of your project will be shared. We’re truly in it together. We put our resources to work so you don’t have to worry about undue stress on your time and budget.

There’s a world of possibilities when we work together. We’d love to hear from you, so contact us at any time.

Meanwhile, we want you to be as informed as possible about which questions to ask and what to look for when evaluating a brake manufacturer, so we’ve put together this guide to help. Click the link below to access it today.

Subscribe to our blog!

Related blogs

Section Intro

Help visitors get the basic idea within a few seconds, so they understand what this section is about.

The Future of Braking: Why Expertise Matters in Integrating Advanced Electronics

Fortunately for today’s drivers and passengers, significant advancements have been made to improve vehicle safety, stability, and performance. Some of the most notable improvements include anti-lock...

The Importance of Specialized Off-Road Vehicle Brake Manufacturing

Every off-road vehicle — from riding lawn mowers to wheel loaders and everything in between — is more complex today than it was in years past. Advancements in mechanics and intricate built-in...

7 Reasons for Brake Failure in Heavy Equipment and How to Avoid Them

Brakes must work, but that doesn’t mean they always do. And when they don’t work when needed in heavy equipment, that puts operations behind schedule and risks profit loss.

In most cases, brake...