The History of Hayes

A Humble Beginning, a Bright Future

From a garage in the Midwest to facilities in Europe — and see what's made us a titan in braking systems.

Decades of Inspired Engineering

In 1946, Hayes Performance Systems began as H-H Products, a Milwaukee manufacturer of parts for outboard motors. It then transformed into an agricultural and small-engine components parts supply company. In the 1950s, Hayes began its involvement with brakes, designing the first disc brake caliper for a go-kart. By 1958, Hayes was manufacturing disc brakes exclusively.

Since Hayes’ humble beginnings in 1946, the company has grown into a multinational business with premier operations in North America, Europe, and Asia. Hayes is recognized as a global braking and suspension systems supplier with core competencies of integrating components and technologies into different setups. Like any good trail, Hayes’ path has had twists and turns. Yet, you’ll see that decade after decade, the drive for innovation has never stopped.

The Hayes Timeline

In 1946, Harold S. Hollnagel, Sr., founder of H-H Products, began what is now known as Hayes Performance Systems in a garage in Milwaukee, Wisconsin. H-H Products offered light stamping, machined parts, and rod and tube bending. Initially, the business was exclusive to the outboard motor industry, but it eventually evolved into an agricultural and small-engine parts supply company. Harold Sr.’s mantra was, “To manufacture a quality part at a fair price.”

At the beginning of the 1950s, the company moved to a new street, and Harold Hollnagel, Jr., joined the business when he and his father worked to design and build disc brakes for Harold Jr.’s go-kart. Harold Jr. wrote: “After spending two years attending the University of Wisconsin School of Engineering, I became interested in the go-kart field, which at that time was becoming a popular new recreational sport for young male enthusiasts. I created and built our first go-kart and realized the need for a good braking system, which gave birth to the development and manufacturing of the H-H Disc Brake."

In 1958, Harold Sr. steered his attention solely toward the manufacturing and marketing of the line of disc brakes he’d patented.

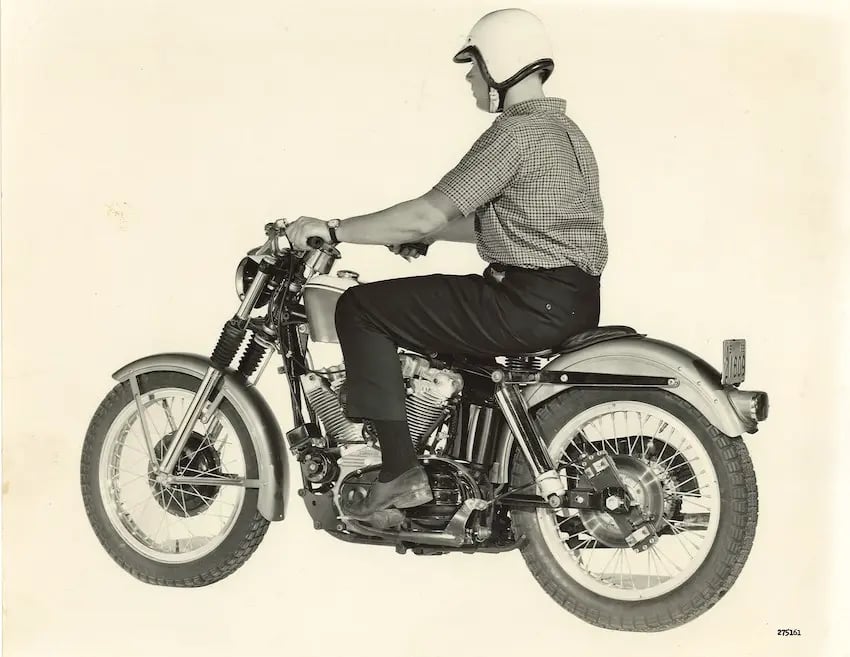

In 1962, H-H Products began working with Harley-Davidson Motorcycle Company on golf cart applications. Shortly after, H-H Products applied for and received two disc brake patents. In 1968, Kelsey-Hayes Co., headquartered in Romulus, Michigan, acquired the company and operated it as the H-H Products Division. The company was then moved to Mequon, Wisconsin, to focus on non-automotive industrial brake components. Soon, the company supplied brakes for all of Harley-Davidson’s motorcycle platforms, most of Caterpillar’s wheel loaders, and Polaris’ snowmobiles.

The 1970s saw noteworthy moments in Hayes history. In October of 1970, the new plant on Donges Bay Road was completed. During this time, H-H was the leading maker of disc brakes for recreational vehicles of all types, as well as an expanded list of industrial, agricultural, garden tractor, construction, and trailer applications.

The Blue Flame — a rocket-power land speed racing vehicle equipped with H-H disc brakes — set a new land speed record of 622.4 MPH on October 23, 1970.

In 1972, H-H Products began supplying disc brake systems to all major snowmobile manufacturers. H-H also manufactured a transmission-mounted disc brake that added immensely to the safety of snowmobiles.

Later that year, the company developed and produced the first disc brakes for the bicycle industry.

On September 30, 1976, the first addition to the Donges Bay Road plant was completed.

Hayes began supplying master cylinders to the powersports industry, and the company became the exclusive supplier of Harley-Davidson’s motorcycle brake systems. Another 1980s milestone: The Brenlin Group purchased Hayes.

H-H supplied Harley-Davidson brakes for all models.

The company developed and patented the first integral water-cooled braking systems for the snowmobile market.

The decade began with the second addition to the plant on August 16, 1990. In 1997, the company introduced the first hydraulic disc brake to the bike segment and formed Hayes Disc Brake to focus on the bicycle industry. Innovations continued in other markets, too, with a heavy-duty mechanical brake and a patented SAHR developed for Caterpillar. Other big news: Hayes became ISO 9001 compliant in 1999.

The development of the first Hayes hydraulic disc brake revolutionized the American mountain bike industry in 1997. This launched the Hayes Bicycle business unit.

Another decade brought about more changes, including another plant addition. Plus, the Brenlin Group recruited a new senior leadership team, which resulted in the implementation of the Hayes Business Operating System (HBOS), consisting of Lean manufacturing and world-class business processes. In addition, we expanded into the ATV/UTV markets. In 2005, Hayes underwent a management buyout and became HB Performance Systems.

The company was organized into four divisions and quickly moved into acquisition mode to strengthen its bicycle offerings. Within a few years, Hayes became the parent company of SUNringlé, Wheelsmith, Answer, and Manitou. These acquisitions also extended our manufacturing footprint into Asia.

The Hayes Bicycle Group was recognized as a “Most Valuable Vendor” in December of 2008 by Merida, a manufacturer of bicycles for OEM brands. This award recognized the quality of Hayes products and the support service we provide.

The 2010s were an eventful decade that saw Hayes opening a European facility outside Munich, Germany. We partnered with two leading defense contractors and developed a new brake system for the JLTV (Joint Light Tactical Vehicle) and introduced TrailTrac® — our proprietary traction control and controlled braking system — for snowmobiles, ATVs, and UTVs. We even delivered the first “plus” sized suspension fork for the bicycle market and launched a new line of ProTaper products for mountain bikes.

Hayes began manufacturing the REFLX 32 and was awarded the JLTV contract with Oshkosh Defense.

Hayes’ Dominion A4 Brake won Pinkbike’s “Component of the Year.” Later, Hayes acquired Reynolds Cycling, a carbon wheel manufacturer, to add to our brands within the bicycle group. With the acquisition, another U.S. office was added in Draper, Utah, for carbon fiber research and development.

Hayes Bicycle Group launched our Performance Youth category of bicycle components. A major advancement in the youth bike sector, this ultimately created the new and popular high-end performance youth mountain bike category that’s since been adopted by all major brands.

While the full story of the 2020s remains to be told, it’s so far been a decade of milestones for Hayes.

Hayes Performance Systems celebrated three years without a Lost-Time Accident at the Mequon facility.

Hayes Performance Systems celebrated 75 years of business.

Proven Past

Hayes Performance Systems is a team of dedicated people who share passion, expertise, and high standards. Everything we do must be: PURPOSEFUL, PREMIUM, TRUSTED, and UNBEATABLE.

We deliver exceptional results through our dedication to the Hayes Business System. This system identifies the importance of customers, motivated and empowered employees, superior products, strategic focus, agility, and accountability. It defines who we are and what it takes to be a world-class company.

Fantastic Future

Purpose and passion fuel our every move — design through delivery. Intentional, inspired teamwork is the foundation of our success.

Driven to deliver excellence, we anticipate what’s next while perfecting what’s possible.

.png?width=850&height=726&name=_K4I1488%201%20(4).png)

History

Would you like to know more about our story or products? We’d love to talk!