Retrofitting Brakes on Agriculture Equipment: What You Need to Know

Share this

It’s not uncommon for agriculture equipment dealers to upgrade components of their older inventory, especially key components like braking systems. In many cases, it makes a lot of sense:

- Upgrading older braking systems can improve the equipment’s stopping power, which in turn enhances safety

- Buyers typically have more confidence purchasing used equipment when its essential components, like brakes, have been swapped for newer versions

- Dealers can get a higher price for equipment with upgraded systems

- Older braking systems may not be in top working order, exposing dealers to potential liability

Dealers aren’t the only ones realizing the benefits of upgrading and retrofitting. Many original equipment manufacturers (OEMs) offer remanufacturing programs, where they take back used equipment, refurbish it to like-new condition, and then resell it with a warranty. Remanufacturing provides a cost-effective option for equipment buyers, and gives OEMs an additional revenue stream.

What To Think About Before You Upgrade

In general, investing in brake system upgrades is a practical way for dealers to add value and improve the saleability of their used inventory. Of course, you also have to weigh the costs against the potential return on that investment, and it may not make sense for every piece of equipment.

The cost to upgrade or retrofit braking systems depends primarily (but not entirely) on these two factors:

Age/hours of the equipment. Newer, lower-hour machines justify higher investment costs because they have more years of operational life; old equipment with very high hours probably won't justify the expense.

Market value of the equipment. Higher-value tractors can absorb more refurbishment costs into their resale prices, while lower-value machines are less likely to recover those costs.

Of these, the age of the tractor is the more important factor. The older the equipment, the less practical it becomes to invest in retrofitting a major system, but it often makes financial sense for equipment less than ten years old.

Can You Retrofit Your Ag/Farm Equipment’s Brakes?

Yes, you can retrofit your ag/farm equipment’s brakes – as long as…

…the new brakes meet performance specs. The new brakes should meet, if not exceed, the original equipment manufacturer's performance specs.

…the brakes you want to install are compatible. A new braking system must o be designed to fit and function properly for the machine specific make, model, and year.

…the brake types are the same. The type of brake being installed (dry disc, drum, wet disc, etc.) must match the existing system. Switching brake types might be possible but not practical because of the added cost.

…the actuation methods are the same. The new braking system’s actuation method (hydraulic, air, mechanical, etc.) should match the existing system’s method.

Once you've reviewed the guidelines for upgrading and retrofitting and gathered all the necessary equipment details, it’s time to talk to the brake experts to help you identify the right system for your equipment.

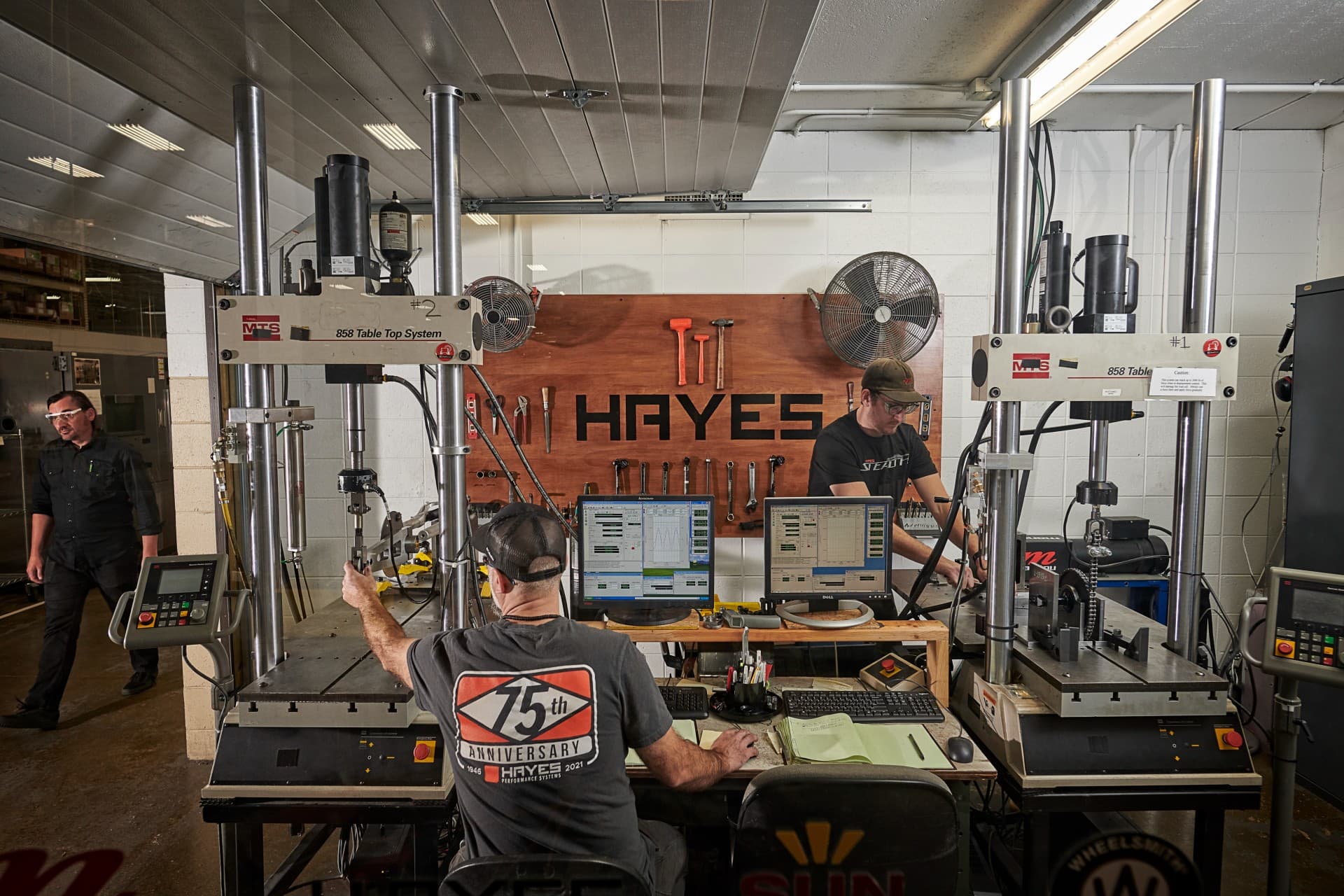

Working with Hayes, you have a wide range of braking systems ideal for your agriculture and farming equipment. Your investment can improve saleability and safety and reduce the likelihood of costly liability that older brakes present. Look at what we have to offer, then reach out to talk with our team.

Subscribe to our blog!

Related blogs

Section Intro

Help visitors get the basic idea within a few seconds, so they understand what this section is about.

Dry Disc Brakes: How Engineering Impacts Performance & Safety

Dry disc braking systems, when they came into widespread use decades ago, represented a significant improvement over drum brakes. They’ve been used ever since in everything from mountain bikes to...

Electric Vehicles and Dry Disc Brakes: A Combination That Promotes Efficiency & Safety

Do electric vehicles (EVs) use the same brake systems as conventional vehicles? Yes and no.

Some light EVs – ebikes and scooters, for example – rely primarily on regenerative braking systems. These...

The Future of Braking: Why Expertise Matters in Integrating Advanced Electronics

Fortunately for today’s drivers and passengers, significant advancements have been made to improve vehicle safety, stability, and performance. Some of the most notable improvements include anti-lock...